The Benefits of Laser Engraving in Modern Manufacturing Education

Understanding Laser Engraving

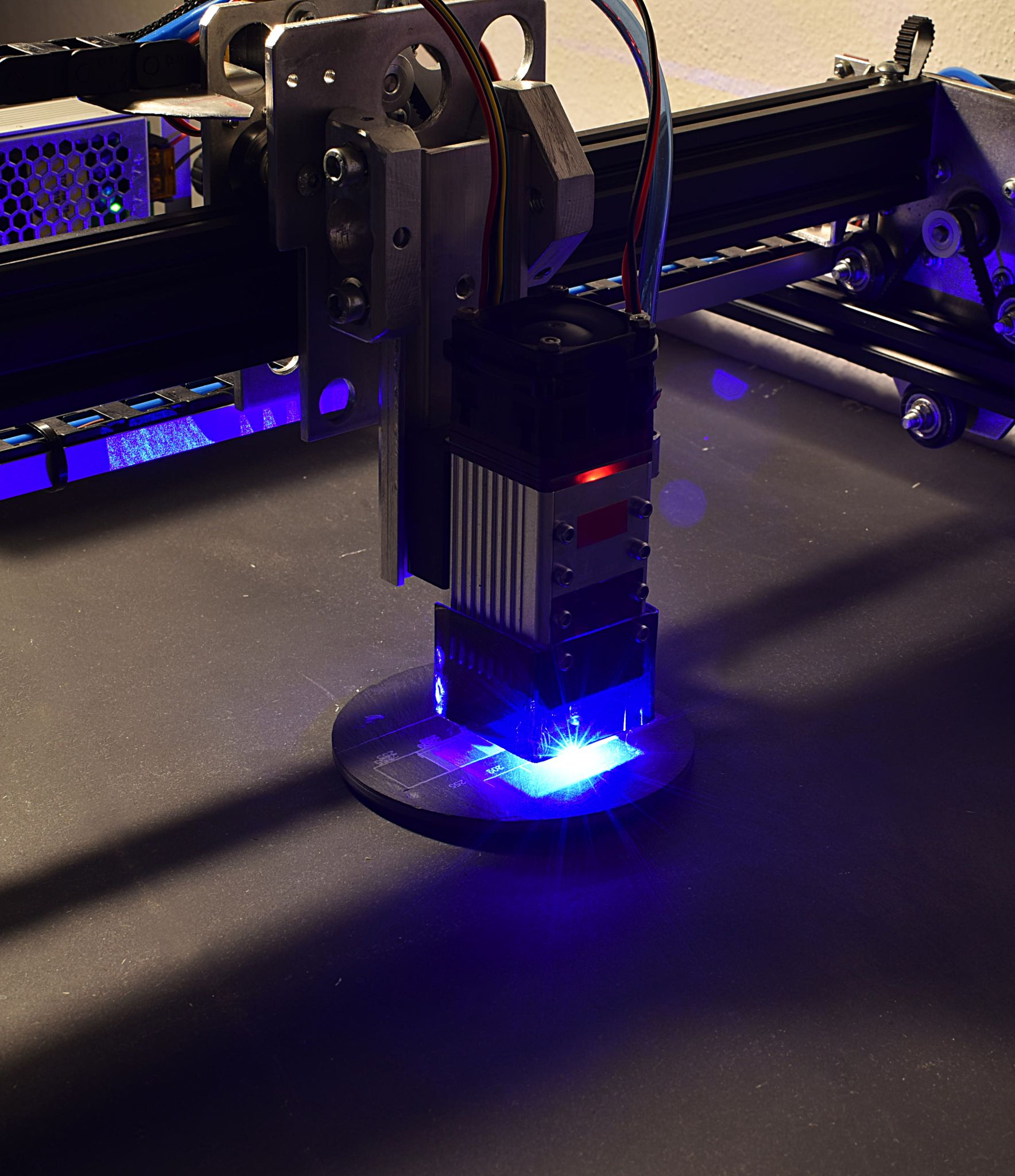

Laser engraving has become a pivotal technology in modern manufacturing education. This precise and efficient technique uses lasers to etch designs, patterns, or text onto various materials, ranging from metals to plastics. By incorporating laser engraving into educational settings, students gain hands-on experience with a technology that's widely used in industries today.

The versatility of laser engraving makes it an essential tool in the curriculum of manufacturing education. Not only does it allow for the creation of intricate designs, but it also enhances the understanding of materials and their properties. Students learn how different materials react to laser exposure, which is crucial for careers in engineering and manufacturing.

Enhancing Technical Skills

One of the primary benefits of integrating laser engraving into manufacturing education is the improvement of technical skills among students. As they work with laser engraving machines, they develop a deeper understanding of computer-aided design (CAD) software. This experience is invaluable as CAD is a cornerstone of modern manufacturing processes.

Moreover, students learn the importance of precision and attention to detail. Laser engraving requires meticulous planning and execution, skills that are transferable to various aspects of manufacturing. As students become proficient with these technologies, they are better prepared for the workforce.

Fostering Creativity and Innovation

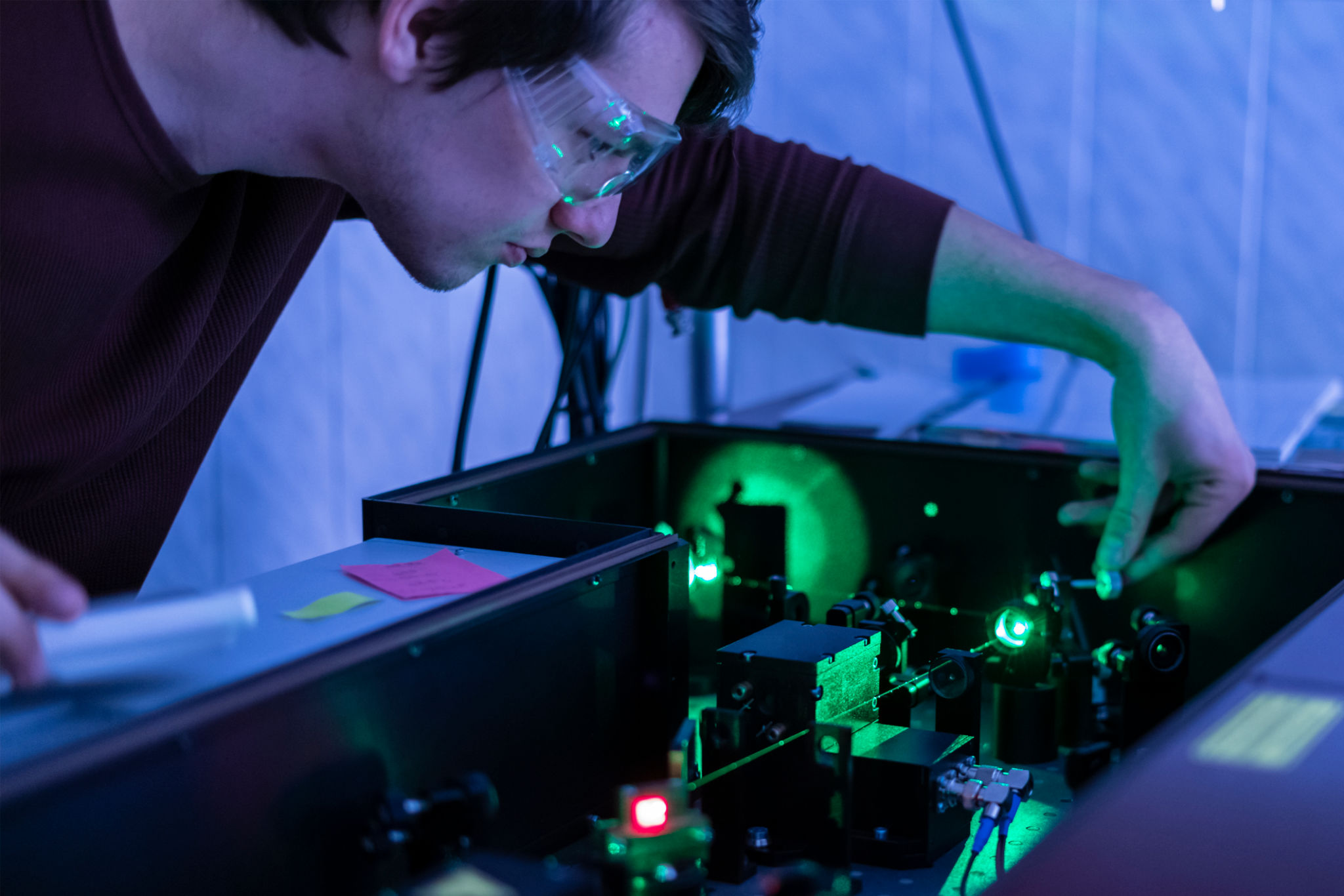

Laser engraving is not only about precision; it also encourages creativity and innovation. Students can explore their artistic side by creating custom designs and experimenting with different materials. This creative freedom fosters a learning environment where innovation is encouraged and celebrated.

Furthermore, by engaging with laser engraving, students can see the tangible results of their creativity. This aspect of manufacturing education helps to inspire future inventors and designers, providing them with the tools and confidence needed to pursue innovative solutions in their careers.

Real-World Applications

The skills acquired through laser engraving education have direct applications in real-world manufacturing scenarios. Industries such as automotive, aerospace, and electronics utilize laser engraving for various purposes, including part identification, branding, and customization.

By understanding these applications, students can see the relevance of their education to real-world challenges. This connection between classroom learning and industry needs helps to motivate students and prepare them for successful careers in manufacturing and engineering fields.

Cost-Effective Learning

Incorporating laser engraving into educational programs can also be cost-effective. While initial investment in equipment may seem significant, the long-term benefits outweigh these costs. Laser engraving machines are durable and require minimal maintenance, making them a sustainable educational tool.

Additionally, by reducing material wastage through precise cutting and engraving, educational institutions can manage resources more efficiently. This aspect not only teaches students about sustainability but also allows schools to allocate funds to other essential areas of their programs.

Conclusion

In summary, laser engraving offers numerous benefits in modern manufacturing education. By enhancing technical skills, fostering creativity, and providing real-world applications, it prepares students for successful careers in various industries. Its cost-effectiveness ensures that educational institutions can offer this technology to students sustainably.

As technology continues to evolve, the integration of tools like laser engraving in education will become increasingly crucial. By investing in these technologies today, we can ensure that future generations are equipped with the skills necessary to thrive in the ever-changing landscape of manufacturing.